W3@Track Loop/RADIAX Health Diagnostic Tool (LHDT)

W3@Track Loop/RADIAX Health Diagnostic Tool (LHDT)

Deteriorated inductive loop/RADIAX communication cable along the guideway stops the train and causes schedule delays in Air Train operation (in JFK or others). Loop/RADIAX Health Diagnostic Tool (LHDT), namely W3@Track, detects and predicts cable issues and makes the system less disruptive and more reliable in a cost-effective way.

How It Works?

Inductive loop/RADIAX cable along the guideway is vital for Air Train (in JFK or others) movement commanded from the central to the train through the loop/RADIAX cable along the guideway. Because of the cable aging, the weather, cable supporter, surrounding metal, etc., the signal gets weak, and the noise increases, which could cause a command message drop and the train timeout (emergency brake). During the incident, the train operator is required to manually drive to reenter the train, which usually causes enormous delays in the schedule for the upcoming trains and causes much inconvenience for travelers, taking an average of 20-25 minutes to recover the regular operation.

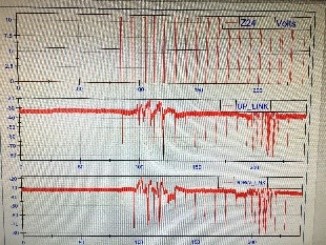

The rail maintenance team performs daily manual inspections and periodic tests to keep the cable well-maintained, but timeout still happens from time to time. W3@Track – Loop/RADIAX Health Diagnostic Tool (LHDT) is a precise diagnostic tool to automatically collect and analyze the signal strength and noise from the system. By combining data fusion with the data log from train operation, LHDT could automatically detect loop/RADIAX cable issues and alert maintenance personnel to when, where, and what is happening to enable precise corrective action to fix the cable issue to prevent the timeout from occurring.

Functions:

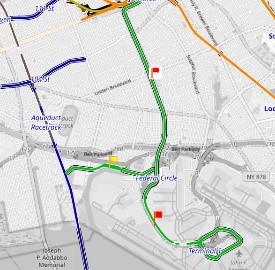

- Red flag (alarm) and yellow flag(alert) in the track guideway map or sheet list to show the faulty loop/ RADIAX section.

- Alert maintenance manager, engineers, and technicians via APP, message, and email.

- Dashboard of red/yellow flag loop/RADIAX versus train timeout incidents.

- Acknowledge the red or yellow flag loop/RADIAX section with the repair/maintenance record.

- Compare the readings before and after the repair or maintenance activity.

Features:

- Track guideway loop/RADIAX section map with a red and yellow flag.

- Click the red or yellow flag in the guideway map to show the detailed loop/RADIAX information such as left or right side, signal strength, and noise chart.

- Sheet list of the red and yellow flag loop/RADIAX section.

- Click the red or yellow flag in the sheet list to show the detailed loop/RADIAX information such as left or right side, signal strength, and noise chart.

- Video or picture display of the red flag and yellow flag loop/RADIAX section.

- Five (5) previous readings in one chart with the baseline signal strength and noise level.

- Data fusion with the train log data for track inspection vehicles.

- Data fusion with the data from operation train logs to correlate between the red/yellow flag loop/ RADIAX section and the operating train timeout.

Benefits:

- Target to reduce downtime caused by faulty loop/RADIAX cable by 80%.

- Accurate diagnostic tool by machine learning to eliminate daily track walk inspection.

- Target to reduce the manual maintenance cost for loop/RADIAX cable by 50%.

- Daytime in-house work instead of night track work to improve employee morale.

- Fewer safety concerns with fewer workers along the track.