W3@Train Centralized Train Diagnostic System (CTDS)

W3@Train Centralized Train Diagnostic System (CTDS)

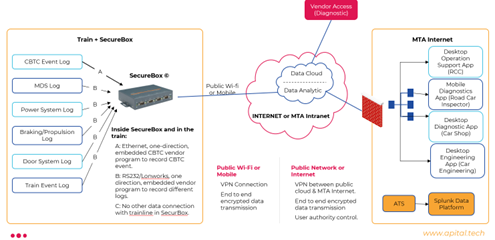

How It Works?

According to McKinsey’s research, predictive maintenance can improve the repair turnaround time by 60% and save 10%-15% in maintenance costs for rail trains. Centralized Train Diagnostic System (CTDS), namely W3@Train, proactively identifies when, where, and what happened or happening in the operating trains to make condition-based and predictive maintenance decisions.

W3@Train, Centralized Train Diagnostic System (CTDS) is a data fusion and analytic data platform that collects and fuses the existing vehicle log data and CBTC system event log data for real-time operational decision-making and predictive vehicle maintenance to ensure a greater quantity and quality trains on the operating lines.

Functions:

- Red flag (alarm) and yellow flag(alert) in the guideway to show faulty trains.

- Red flag (alarm) and yellow flag(alert) in the sheet list to show faulty trains.

- Alert vehicle maintenance manager managers, engineers, and technicians via the app, message, and email for proactive actions.

- Vehicle fault tree and failure detection logic define, refine, and adjust.

- Record the repair activities associated with red Flag and yellow Flag Vehicle alarms.

Features:

- Guideway map-based red and yellow flag trains.

- Click each red or yellow flag in the guideway map to show the detailed train failure, operation recommendation, and others.

- Sheet list of the red flag and yellow flag trains.

- Click each red or yellow flag in the sheet list to show details about train failure, operation recommendations, and others.

- Historic incidents for each train with the repair/maintenance record.

- Data fusion with the data from CBTC (ATS) systems to cross-check the train alarms.

- Data fusion with the database from the CBTC database to ensure guideway map data consistency.

Benefits:

- Reduce operation DOWN TIME for each train set.

- Reduce time spend on the troubleshooting, and repair cycle in the shop/yard.

- Increase passenger satisfaction.

- Cost saving by reducing repair cycle, proactive maintenance, and decreased new train procurement.